Answer:

Explanation:

a) This is a binomial distribution.

p = probability it is defective = 3% = 0.03, q = 1 - p = 1 - 0.03 = 0.97

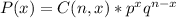

This is a binomial distribution is given by the formula:

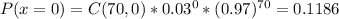

But n = 70

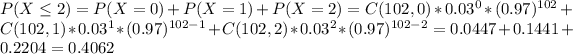

b) n = 102. Hence there can be 2 defective components, hence:

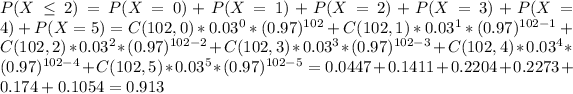

c) n = 105, there can be 5 defective products: