Answer:

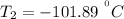

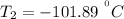

a) the temperature to which the pin must be cooled for assembly is

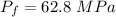

b) the radial pressure at room temperature after assembly is

c) the safety factor in the resulting assembly = 6.4

Step-by-step explanation:

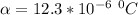

Coefficient of thermal expansion

Yield strength

= 400 MPa

= 400 MPa

Modulus of elasticity (E) = 209 GPa

Room Temperature

= 20°C

= 20°C

outer diameter of the collar

inner diameter of the collar

pin diameter

=

=

Clearance c = 0.06 mm

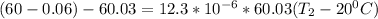

a)

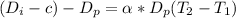

The temperature to which the pin must be cooled for assembly can be calculated by using the formula:

-0.09 =

-0.09 =

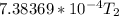

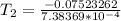

=

=

−0.07523262 =

b)

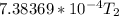

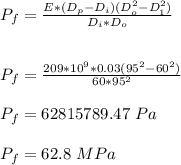

To determine the radial pressure at room temperature after assembly ;we have:

c) the safety factor of the resulting assembly is calculated as:

safety factor =

safety factor =

safety factor = 6.4

Thus, the safety factor in the resulting assembly = 6.4