Answer:

a) 28 stations

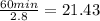

b) Rp = 21.43

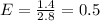

E = 0.5

Step-by-step explanation:

Given:

Average downtime per occurrence = 5.0 min

Probability that leads to downtime, d= 0.01

Total work time, Tc = 39.2 min

a) For the optimum number of stations on the line that will maximize production rate.

Maximizing Rp =minimizing Tp

Tp = Tc + Ftd

At minimum pt. = 0, we have:

dTp/dn = 0

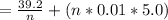

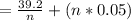

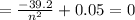

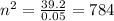

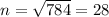

Solving for n²:

The optimum number of stations on the line that will maximize production rate is 28 stations.

b)

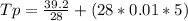

Tp = 1.4 +1.4 = 2.8

The production rate, Rp =

The proportion uptime,