Complete Question:

Some aircraft component is fabricated from an aluminum alloy that has a plane strain fracture toughness of 35MPa√m. It has been determined that fracture results at a stress of 250 MPa (36,250 psi) when the maximum (or critical) internal crack length is 2.0 mm (0.08 in.). For this same component and alloy, will fracture occur at a stress level of 325 MPa (47,125 psi) when the maximum internal crack length is 1.0 mm (0.04 in.)? Why or why not?

Answer:

Fracture will not occur

Reason: Because the fracture toughness = 32.20MPa√m which is less than the material toughness = 35MPa√m. The fracture toughness is not enough to make the material fracture.

Step-by-step explanation:

Critical Stress,

Internal crack length, a = 2 mm

a = l/2 = 2/2 = 1mm

a = 10⁻³ m

Toughness of the material,

For the aluminium alloy to fracture, the material toughness,

Where

is the fracture toughness

is the fracture toughness

Where Y is a dimensionless parameter.

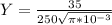

Using the critical stress crack propagation equation, let us find the dimensionless parameter:

Y = 2.5

For a stress level of 325 MPa,

at maximum internal crack length, l = 1.0 mm =

at maximum internal crack length, l = 1.0 mm =

m

m

a = 0.0005 m

Since

is less than the material toughness at a stress level of 325 MPa, fracture will not occur

is less than the material toughness at a stress level of 325 MPa, fracture will not occur