Answer:

check the explanation

Step-by-step explanation:

1.

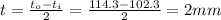

Thickness Loss =

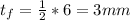

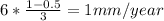

Hence Rate of Corrosion =

= 0.03 inches per year

= 0.03 inches per year

2.

As the expected future life is 7 years,

40 carbon steel pipe has to be replaced every 3 years as given in the question,

Cost per unit length is the sum of material cost and installation cost.

Cost of 40 carbon steel = (5 dollars + 16.5 dollars) * 3 = 64.5 dollars

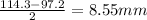

For 80 carbon steel pipe, first calculate the thickness loss,

The critical thickness is given to be 3mm, Hence change in thickness is 8.55-3 = 5.5mm

This 80 carbon steel pipe has to be replaced one more time

Hence, Cost per unit length is the sum of material cost and installation cost.

Cost of 80 carbon steel = (8.3 dollars + 16.5 dollars) * 2 = 49.6 dollars

The best is of stainless steel which does not undergo corrosion at all and thus it needs to be replaced only once throughout the plant operation. Its cost = 24.8 dollars + 16.5 dollars = 41.3 dollars

Hence, stainless steel is the recommended pipe to be used.