Answer:

Assuming 312 operating days, the number of days between orders will be

= 312 days / 26 orders

= 12 days

Step-by-step explanation:

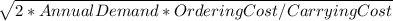

EOQ =

Annual demand = weekly usage * assumed number of weeks in a year

= 4 pounds * 52 weeks

= 208 pounds

Carrying cost for the year = $1 * 52 weeks = $52

Ordering cost = $8

∴ EOQ =

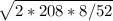

=

=

Economic Order Quantity = 8 pounds

Since EOQ is 8 pounds and annual demand is 208 pounds

∴ number of orders in the year = 208/8

= 26 orders