Answer:

Non steady state process

Because D ∝ 1/t

Step-by-step explanation:

Here we have

Where:

= 0.0025 % by weight of N

= 0.0025 % by weight of N

= 0.45 % by weight of N

= 0.45 % by weight of N

= 0.12 % by weight of N

= 0.12 % by weight of N

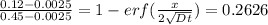

Therefore,

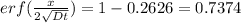

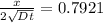

From the inverse erf function we have

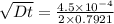

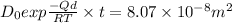

Since x = 0.45 mm, we have

and

and

Dt = 8.069×10⁻⁸ m²

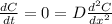

For steady state

Since Dt = 8.069×10⁻⁸ m² = Constant, then as the time increases the diffusion rate decreases hence the process is not steady state.

D is inversely proportional to t.