Answer:

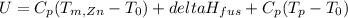

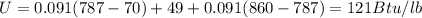

a) The unit energy for melting and pouring is 121 Btu/lb

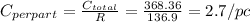

b) The total cost per hour is 368.31/h

c) The cost per part is 2.7/pc

Step-by-step explanation:

a) The unit energy for melting and pouring is:

If we assume that the surrounding temperature is 70°F

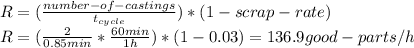

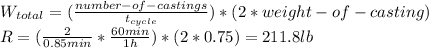

b) The hourly production is:

The total weight of zinc is:

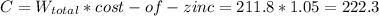

The total cost of zinc is:

$

$

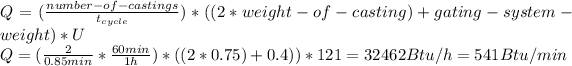

The total heat transfer is:

541 Btu/min = 9.51 kW

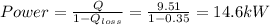

The power is:

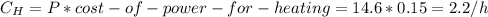

The hourly cost is:

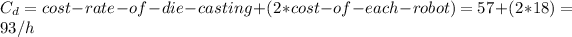

The cost for die casting is:

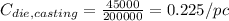

The die cost per casting is:

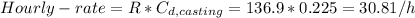

The hourly rate is:

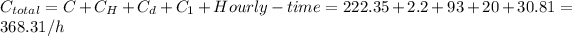

The total cost per hour is:

c) The cost per part is: