Here is the full question

A rectangular beam made of ABS plastic ( ) has dimensions b = 20 mm deep and t = 10 mm thick. Loads in the plane of the 20mm depth cause a bending moment of 10 N.m. What is the largest through thickness edge crack that can be permitted if a factor of safety of 2.5 against fracture is required?

Answer:

1.62 mm

Step-by-step explanation:

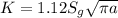

The formula for the stress intensity factor (K) for various bending, curves and equation label is expressed as:

where

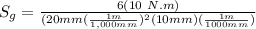

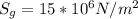

= gross section nominal stress for center cracked plate of ABS plastic rectangular beam and it's given as:

= gross section nominal stress for center cracked plate of ABS plastic rectangular beam and it's given as:

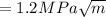

To determine the stress intensity factor K ; we have:

K =

From the table of fracture toughness of polymers and ceramics at room temperature, we selected the fracture toughness of ABS plastics material to be :

So; K =

The largest through thickness edge crack that can be permitted due to bending moment of 10 N.m is :

a =

a = 0.00162 m

a = 1.62 mm

Thus , the largest through thickness edge crack that can be permitted due to bending moment of 10 N.m is 1.62 mm