Answer:

(a) 0.1326

(b) 0.2732

(c) 0.0410

Explanation:

Let X = number of defective components.

The probability of X is, P (X) = p = 0.02.

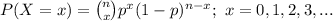

The random variable X follows a Binomial distribution with parameters n and p. The probability mass function of a Binomial distribution is:

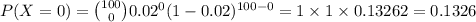

(a)

Compute the probability that the 100 orders can be filled without reordering components as follows:

n = 100

Thus, the probability that the 100 orders can be filled without reordering components is 0.1326.

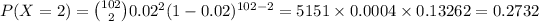

(b)

Compute the probability that out of 102 orders 2 orders needs reordering as follows:

n = 102

Thus, the probability that out of 102 orders 2 orders needs reordering is 0.2732.

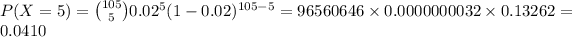

(c)

Compute the probability that out of 105 orders 2 orders needs reordering as follows:

n = 105

Thus, the probability that out of 105 orders 5 orders needs reordering is 0.0410.