Answer:

We need a sample size of 600 or higher in order to make us 95 percent confident that the sample mean bolt length is within .02 inches of the true mean bolt length

Explanation:

We have that to find our

level, that is the subtraction of 1 by the confidence interval divided by 2. So:

level, that is the subtraction of 1 by the confidence interval divided by 2. So:

Now, we have to find z in the Ztable as such z has a pvalue of

.

.

So it is z with a pvalue of

, so

, so

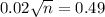

Now, we find the margin of error M as such

In which

is the standard deviation of the population and n is the size of the sample.

is the standard deviation of the population and n is the size of the sample.

How many bolts should be sampled in order to make us 95 percent confident that the sample mean bolt length is within .02 inches of the true mean bolt length?

We need a sample size of n or higher, when

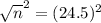

. So

. So

We need a sample size of 600 or higher in order to make us 95 percent confident that the sample mean bolt length is within .02 inches of the true mean bolt length