Answer:

Now we can solve for the fracture level with this formula:

We can use the parameter of Y from the previous equation since this value not changes.

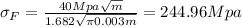

And replacing we have:

And for this case we see that this value not correspond to 260 Mpa the value reported, so then the correct answer for this case would be 244.96 Mpa for the new crack length of 6mm = 0.006 m

Step-by-step explanation:

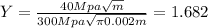

We need to solve for the parameter Y given by this expression:

Where:

represent the fracture toughness

represent the fracture toughness

represent the stress level

represent the stress level

And if we replace we got:

Now we can solve for the fracture level with this formula:

We can use the parameter of Y from the previous equation since this value not changes.

And replacing we have:

And for this case we see that this value not correspond to 260 Mpa the value reported, so then the correct answer for this case would be 244.96 Mpa for the new crack length of 6mm = 0.006 m