Answer:

True

Explanation:

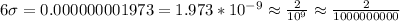

A six sigma level has a lower and upper specification limits between

and

and

. It means that the probability of finding no defects in a process is, considering 12 significant figures, for values symmetrically covered for standard deviations from the mean of a normal distribution:

. It means that the probability of finding no defects in a process is, considering 12 significant figures, for values symmetrically covered for standard deviations from the mean of a normal distribution:

For those with defects operating at a 6 sigma level, the probability is:

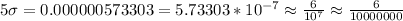

Similarly, for finding no defects in a 5 sigma level, we have:

.

.

The probability of defects is:

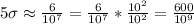

Well, the defects present in a six sigma level and a five sigma level are, respectively:

Then, comparing both fractions, we can confirm that a 6 sigma level is markedly different when it comes to the number of defects present:

[1]

[1]

[2]

[2]

Comparing [1] and [2], a six sigma process has 2 defects per billion opportunities, whereas a five sigma process has 600 defects per billion opportunities.