Answer:

Step-by-step explanation:

From the given information:

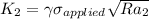

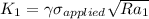

The first thing we need to do is to use the formula used in-plane strain fracture toughness to determine the geometry factor

i.e

where;

a = crack length

geometry factor

geometry factor

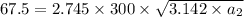

In the first scenario, where;

Plain fracture toughness

radius(R) = 3.142

Then, replacing it into the above equation, we have:

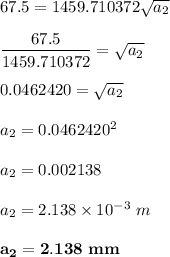

Now, since we've determined the geometry factor, it will be easier to estimate the max. allowable surface length.

∴