Answer:

Step-by-step explanation:

Given that:

diameter = 100 mm

initial temperature = 500 ° C

Conventional coefficient = 500 W/m^2 K

length = 1 m

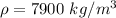

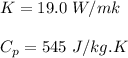

We obtain the following data from the tables A-1;

For the stainless steel of the rod

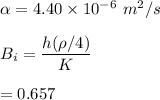

Here, we can't apply the lumped capacitance method, since Bi > 0.1

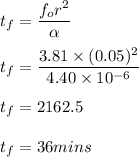

However, on a single rod, the energy extracted is:

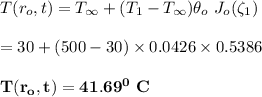

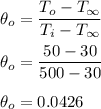

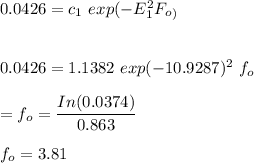

Hence, for centerline temperature at 50 °C;

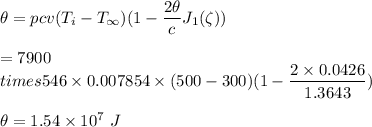

The surface temperature is: