Answer:

a)

= 133.75 Gpa

= 133.75 Gpa

b) Fnet = 560 N

c) thermal expansion of the composite material = 14.31

/ °C

/ °C

Step-by-step explanation:

Solution:

a) Elastic Modulus of the composite:

Area of steel wire =

x (

x (

) = 0.8 x

) = 0.8 x

Area of Copper wire =

x (

x (

) - 0.8 x

) - 0.8 x

Area of Copper wire = 2.4 x

Young's Modulus of Composite mixture:

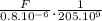

=

=

+

+

Equation 1

Equation 1

here,

= Stress in Steel

= Stress in Steel

= Stress in Copper.

= Stress in Copper.

We know that,

F = P/A

F is inversely proportional to Area, so if area is large, stress will less and vice versa. So, Take

Ratio for area of steel =

Ratio for area of steel =

= 0.25

= 0.25

Similarly, for Copper,

Ratio for area of copper =

Ratio for area of copper =

= 0.75

= 0.75

Put these values in equation 1:

=

=

+

+

= (0.25)

= (0.25)

+ (0.75)

+ (0.75)

We are given that,

= 205 Gpa

= 205 Gpa

= 110 Gpa

= 110 Gpa

So,

= (0.25) (205 Gpa) + (0.75) (110 GPa)

= (0.25) (205 Gpa) + (0.75) (110 GPa)

= 51.25GPa + 82.5 Gpa

= 51.25GPa + 82.5 Gpa

Hence, the Elastic Modulus of the composite will be:

= 133.75 Gpa

= 133.75 Gpa

b) maximum force:

Fnet = Fst + Fcu

We know that F = (Yield Stress x Area)

F = fst x Ast + fcu x Acu

And we are given that,

Yield stress of Steel = 280 Mpa

Yield stress of Copper = 140 Mpa

And,

Ast = 0.8 x

Acu = 2.4 x

Just plugging in the values, we get:

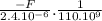

F = (280 Mpa) (0.8 x

) + (140 Mpa) (2.4 x

) + (140 Mpa) (2.4 x

)

)

F = 224 + 336

Fnet = 560 N ( because Mpa =

N/

N/

)

)

So, it means the composite will carry the maximum force of 560N

c) Coefficient of Thermal Expansion:

Strain on both material is same upon loading so,

(ΔL/L)st = (ΔL/L)cu

by thermal expansion equation:

(

ΔT +

ΔT +

) =

) =

ΔT +

ΔT +

)

)

Where

= Coefficient of Thermal expansion

= Coefficient of Thermal expansion

Here, fst = -fcu = F

and ΔT = 1°

So,

Plugging in the values, we get.

( 10 x

x (1) +

x (1) +

) = ( 17 x

) = ( 17 x

x (1) +

x (1) +

)

)

Solving for F, we get:

F = 0.71 N

Here,

fst = F = 0.71 N (Tension on Heating)

fcu = -F = 0.71 N ( Compression on Heating )

So, the combined thermal expansion of the composite material will be:

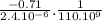

(ΔL/L)cu = ( 17 x

x (1°) +

x (1°) +

)

)

(ΔL/L)cu = ( 17 x

x (1°) - 2.69 x

x (1°) - 2.69 x

combined thermal expansion of the composite material = 14.31

/ °C

/ °C