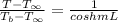

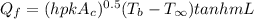

a) We start calculating the temperature through the Temperature Distribution equation, which is

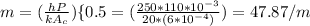

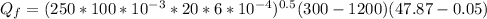

First with our values, we calculate the parameter m,

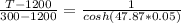

Replacing ,

We realize that the temperature is below the 1050 allowed. Using techniques to reach the target temperature are recommended.

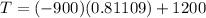

b) To calculate the heat rate, we only apply its equation, that is,

There is a loss of 508W