Answer:

maximum allowable surface crack length is 1.08 mm

Step-by-step explanation:

given data

stress σ = 250 MPa

length of a surface crack = 1.6 mm

plane-strain fracture toughness = 62 MPa

solution

we will calculate here design parameter by design stress equation that is

...................1

...................1

here σ is stress given 250 and a is length of a surface crack and K is plane strain fracture toughness so Y will be here

250 =

Y = 3.49798

so

now we find maximum allowable surface crack length for another alloy using relation

................2

................2

so a will be here

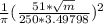

a =

put here value

a =

a = 0.001082 m

a = 1.08 mm

so maximum allowable surface crack length is 1.08 mm