Answer:

Yes, fracture will occur

Step-by-step explanation:

Half length of internal crack will be 4mm/2=2mm=0.002m

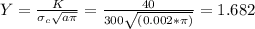

To find the dimensionless parameter, we use critical stress crack propagation equation

and making Y the subject

and making Y the subject

Where Y is the dimensionless parameter, a is half length of crack, K is plane strain fracture toughness,

is critical stress required for initiating crack propagation. Substituting the figures given in question we obtain

is critical stress required for initiating crack propagation. Substituting the figures given in question we obtain

When the maximum internal crack length is 6mm, half the length of internal crack is 6mm/2=3mm=0.003m

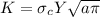

and making K the subject

and making K the subject

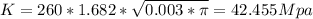

and substituting 260 MPa for

and substituting 260 MPa for

while a is taken as 0.003m and Y is already known

while a is taken as 0.003m and Y is already known

Therefore, fracture toughness at critical stress when maximum internal crack is 6mm is 42.455 Mpa and since it’s greater than 40 Mpa, fracture occurs to the material