Answer:

42.85 m/min

Step-by-step explanation:

To save cost, the tools should not be changed frequently if the tool cost or tool change time is high

The tooling cost per cutting edge =

= $4.25

= $4.25

n = 0.13, C=75 (m/min), tool change time =

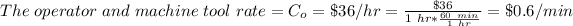

Therefore the cutting speed for minimum cost is given as:

![v_(max)=(C)/([(C_o)/(((1)/(n)-1 )(C_o*t_t+c_t)) ]^n) \\\\Substituting:\\\\v_(max)=75{[(0.6)/(((1)/(0.13)-1 )(0.6*4+4.25)) ]^(0.13)} \\\\v_(max)=42.85\ m/min](https://img.qammunity.org/2021/formulas/engineering/college/9vzbc38hfqa9iypcnvpl7pqylsotil2u3f.png)