Answer:

a) 749

b) 4.073

Step-by-step explanation:

Given:

Mean = demand = 80 pounds

Standard deviation of demand = 10 pounds

Lead time = 8 days

Standard deviation of lead time = 1 day

a) What ROP would provide a stock out risk of 10 percent during lead time.

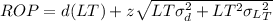

To find this re-order point (ROP) quantity, take the formula:

Here, service level = 100%-10% = 90%,

Thus z at 90% = ±1.28

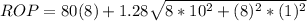

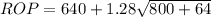

= 640 + 1.28* 84.85

= 748.61

≈ 749 units

b) What is the expected number of units (pounds) short per cycle.

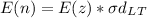

Find the number of units shorts per cycle. Take the formula:

[

Where E(z) = standardized number of shorts = 0.048

= standard deviation of lead time demand = 84.85

= standard deviation of lead time demand = 84.85

Therefore,

E(n) = 0.048 * 84.85

= 4.073