Answer:

Explanation:

Given that,

μ = 25.1

σ = 0.26

a) since standard deviation is ideal measure of dispersion , a combination of control chart for mean x and standard deviation known as

Chart is more appropriate than

and R - chart for controlling process average and variability

and R - chart for controlling process average and variability

so we use

charts

charts

b)

n = 11

we have use 2 σ confidence

so, control unit for

chart are

chart are

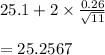

upper control limit =

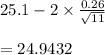

lower control limit =

control limit = μ

μ = 25.1

upper control limit =

lower control limit =

Upper control limit and lower control limit are in between the specification limits , that is in between 24.9 and 25.6

so, process is in control

c) if we use 3 sigma limit with n = 11

then

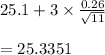

upper control limit =

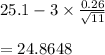

lower control limit =

control limit is 25.1

Then, process is in control since upper control limit and lower control limit lies between specification limit

So, process is in control