Answer:

Explanation:

Given that :

sample mean = 4.001 inches

sample standard deviation = 0.002 inch

a.

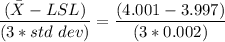

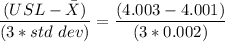

![C_(pk) = min [((USL- \bar X))/((3*std \ dev)) \ ; \ ( (\bar X- LSL))/((3*std \ dev))]](https://img.qammunity.org/2021/formulas/mathematics/college/hje2n14jqg58i1ac3cm197wcgdfmhoyqok.png)

specification =

Upper specification limit USL = 4 + 0.003 = 4.003

Lower specification limit LSL = 4 - 0.003 = 3.997

Thus ;

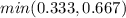

= 0.333

= 0.333

is a measure of closeness to one's target and the consistency around the average performance.

is a measure of closeness to one's target and the consistency around the average performance.

b) No, C - spec should not use this machine to produce this part because

< 1.33 which typical means that the part is not fully capable of hitting the target specification on a consistent basis .

< 1.33 which typical means that the part is not fully capable of hitting the target specification on a consistent basis .