Answer:

a)

0.167

b)

No

Step-by-step explanation:

Given that:

The specification limits are 5 ± 0.003 inches, The sample mean (μ) = 5.002 inches, the standard deviation (σ) = 0.002 inch

a)

The interval of the specification is (5 - 0.003, 5 + 0.003 )

The Upper specification limit (USL) = 5 + 0.003 = 5.003 inches

The lower specification limit (LSL) = 5 - 0.003 = 4.997 inches

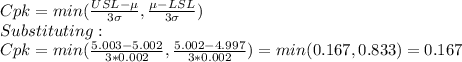

The formula for Cpk is given by the equation:

The Cpk is 0.167

b)

No, since the Cpk is less than 1, it means that variation is too wide compared to the specification therefore the machine is not capable of producing the part at the desired quality level.