Answer:

1. 4,000 bags

2. 1,000

3. 180 runs

4. 18,000

5. $165,600

Step-by-step explanation:

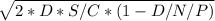

1.

Q =

= 4,000 bags

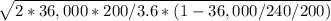

2.

Maximum Inventory = Q* (1 - D/N/P)

4,000*0.25

= 1,000

3.

Annual demand / Bags of coffee roasted per day

36,000 bags / 200 bags

= 180 runs

4.

Annual average inventory

36,000/2

=18,000

5.

Production Cost $200 * 180 runs = $36,000

Carrying Cost $3.6 * 36,000 bags = $129,600

Total Cost = $36,000 + $129,600

= $165,600