Answer:

It can be used the confidence interval to check the idea.

The confidence interval tells us that the real mean is expected to be between 40.2 and 40.4, with a 95% of confidence.

We can conclude that the mean diameter has moved away from the target value.

Explanation:

A method to determine wether the mean diameter has moved away from the target is to calculate a confidence interval over the mean.

This would let us know if the real mean diameter could be 40 mm or not.

If the confidence interval does not include the value 40 mm, we can claim that the mean diameter has moved from the target value.

We will calculate a 95% confidence interval (CI), for which the z-value is z=1.96.

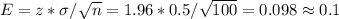

The margin of error is:

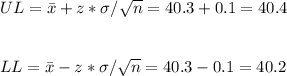

Then, the upper and lower limits of the CI are:

The confidence interval tells us that the real mean is expected to be between 40.2 and 40.4, with a 95% of confidence.

We can conclude that the mean diameter has moved away from the target value.