Step-by-step explanation:

Strengthening by grain size reduction

- It is based on the fact that dislocations will experience hindrances while trying to move from a grain into the next because of abrupt change in orientation of planes.

- Hindrances can be two types: forcible change of slip direction, and discontinuous slip plane.

- Smaller the grain size, often a dislocation encounters a hindrance. Yield strength of material will be increased.

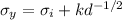

- Yield strength is related to grain size (diameter, d ) as Hall Petch relation:

Strengthening by Grain size reduction (contd..)

- Grain size reduction improves not only strength, but also the toughness of many alloys.

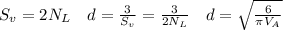

- If d is average grain diameter,

is grain boundary area per unit volume,

is grain boundary area per unit volume,

is mean number of intercepts of grain boundaries per unit length of test line,

is mean number of intercepts of grain boundaries per unit length of test line,

is number of grains per unit area on a polished surface:

is number of grains per unit area on a polished surface:

- Grain size can also be measured by comparing the grains at a fixed magnification with standard grain size charts.

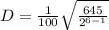

- Other method: Use of ASTM grain size number (Z). It is related to grain diameter, (in mm) as follows:

Solid solution strengthening

- Impure foreign atoms in a single phase material produces lattice strains which can anchor the dislocations.

- Effectiveness of this strengthening depends on two factors size difference and volume fraction of solute. Solute atoms interact with dislocations in many ways:

- elastic interaction

- modulus interaction

- stacking-fault interaction

- electrical interaction

- short-range order interaction

- long-range order interaction