Answer:

Part (a)

Eₓ = 142.1 GPa

Part (b)

Load carried by carbon fiber = 98.5%

Part (c)

F (fiber) = 14776.1 N

F (matrix) = 221.63 N

Step-by-step explanation:

Given data:

Carbon-Epoxy composite

Carbon fibers = 40%

Epoxy fibers = 60%

Modulus of elasticity of carbon fibers = 350 GPa

Modulus of elasticity of Epoxy fibers = 3.5 GPa

Longitudinal stress = 60 MPa

Cross-sectional area = 250 mm^2

Solution:

Part (a)

Modulus of Elasticity of composite material = Eₓ = E₁V₁ + E₂V₂

Eₓ = Modulus of Elasticity of composite material

E₁ = Modulus of Elasticity of carbon fibers

V₁ = % of carbon fibers

E₂ = Modulus of Elasticity of epoxy fibers

V₂ = % of epoxy fibers

Eₓ = 350*0.4 + 3.5*0.6

Eₓ = 142.1 GPa

Part (b)

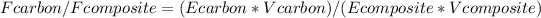

Load carried by carbon fiber

Put,

V composite = 1

E composite = 142.1 GPa

E carbon = 350 GPa

V carbon = 0.4

= (350*0.4) / (142.1*1)

= 0.985

Load carried by carbon fiber = 98.5%

Part (c)

First calculate ratio of fiber load to matrix load

= (350*0.4) / (3.5*0.6) (F represents force or load)

= (350*0.4) / (3.5*0.6) (F represents force or load)

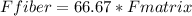

= 66.67 ................... Eq (1)

= 66.67 ................... Eq (1)

Total force sustained by composite material

= Applied stress * Cross-sectional area

Fₓ = 60 MPa * 250 mm^2

Fₓ = 15,000 N

This total load is carried by both fibers and matrix phases. So,

Fₓ = F (fiber) + F (matrix)

Put values in above equation

15,000 = (66.67 * F (matrix)) + F (matrix)

15,000 = 67.67 F (matrix)

F (matrix) = 221.63 N

Put F (matrix) = 221.63 N in equation (1)

F (fiber) = 221.63 * 66.67

F (fiber) = 14776.1 N