Answer:

7.3% of the bearings produced will not be acceptable.

Explanation:

We are given the following information in the question:

Mean, μ = 0.499 inch

Standard Deviation, σ = 0.002 inch

We are given that the distribution of the diameters is a bell shaped distribution that is a normal distribution.

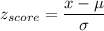

Formula:

A bearing is acceptable if its diameter is within 0.004 inches that is the range is from 0.496 inch to 0.504 inches.

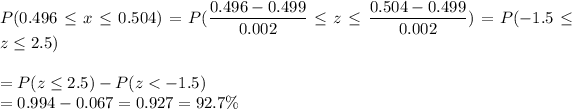

P(diameter between 0.496 inch and 0.504 inch)

Percentage of the bearings produced will not be acceptable =

Thus, 7.3% of the bearings produced will not be acceptable.