Answer:

The true stress at true strain 0.05cm/cm is 80MPa

Step-by-step explanation:

Given that

the strength coefficient is K

true strain is ε

strain hardening exponent is n

initial diameter of bar is d = 1cm, (10mm)

tensile force is F

engineering stress(S) = 120

the engineering stress(S) =

To find force (F) =

120 =

F = 120 * (π/4) * (100)

F = 9425N

Calculate the true strain (ε) = In (l₀ / l₁)

where

l₀ = initial length of the metallic bar = 3cm

l₁ = final length of metallic bar = 3.5cm

ε = In (3.5 / 3)

= In 1.1667

= 0.154cm/cm

Calculate the true stress (σ) at fracture point

=

tensile force is F and final diameter of bar is d₁ (d in the eqn)

Substitute 9425 N for F and 0.926 cm (9.26mm) for d₁ (d in the eqn)

σ =

= 140MPa

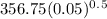

To find the strength coefficient (K) of the material bar

K =

K =

= 356.75MPa

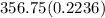

To calculate the true stress σ true strain of 0.05cm/cm

K = 356.75MPa

σ =

=

= 80MPa

The true stress at true strain 0.05cm/cm is 80MPa