Answer:

The right solution is:

(a) 4,272 units

(b) $134.16

(c) $134.17

(d) $12,268.33

Step-by-step explanation:

Seems that the given question is incomplete. The attachment of the complete question is provided below.

According to the question, the values are:

Annual demand,

D = 12,000

Number of days,

= 300

Daily demand,

d =

= 40

Production rate,

P = 100

Ordering cost,

S = $50

Holding cost,

H = $0.10

(a)

The production run's optimal size will be:

Q =

By putting the values, we get

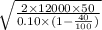

=

=

=

or,

=

(b)

The average holding cost will be:

=

![(Q)/(2)* H* [1-(d)/(P) ]](https://img.qammunity.org/2022/formulas/business/high-school/2x7090gudvvu8oxvf9cu4w3mnv847p40sw.png)

=

![(4472)/(2)* 0.10* [1-(40)/(100) ]](https://img.qammunity.org/2022/formulas/business/high-school/x1ojwoovtjgbgm3gdv62mc1txrgr418an8.png)

=

($)

($)

(c)

The average setup cost will be:

=

=

=

($)

($)

(d)

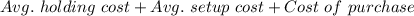

The total cost per year will be:

=

=

=

($)

($)