Answer:

13.9357 horse power

Step-by-step explanation:

Annealed copper

Given :

Width, b = 9 inches

Thickness,

inches

inches

K= 90,000 Psi

μ = 0.2, R = 14 inches, N = 150 rpm

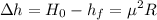

For the maximum possible draft in one pass,

inches

inches

= 1.64 inches

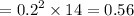

Roll strip contact length (L) =

= 2.8 inches

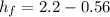

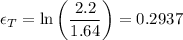

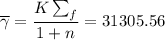

Absolute value of true strain,

Average true stress,

Psi

Psi

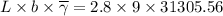

Roll force,

= 788,900 lb

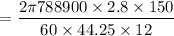

For SI units,

Power =

= 10399.81168 W

Horse power = 13.9357