Answer:

Critical Flaw Length=17.08 mm

The Critical flaw Length > 4mm, It means it is detectable.

Step-by-step explanation:

Given Data:

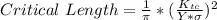

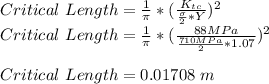

Fracture Toughness=

=88MPa

=88MPa

Yield Strength=σ=710 MPa

Y=1.07

Solution:

Formula:

Since yield Strength is half, Critical Length will be:

Critical Flaw Length=17.08 mm

The Critical flaw Length > 4mm, It means it is detectable.