Answer:

Step-by-step explanation:

From the information given:

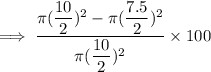

original diameter

= 10 mm

= 10 mm

final diameter

7.5 mm

7.5 mm

Cold work tensile strength of brass = 380 MPa

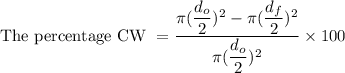

Recall that;

→ At 43.87% CW, Brass has a tensile strength of around 550 MPa, which is greater than 380 MPa.

→ At 43.87% CW, the ductility is less than 5% EL, As a result, the conditions aren't met.

To achieve 15% EL, 28% CW is allowed at most

i.e

The lower bound cold work = 15%

The upper cold work = 28%

The average =

= 21.5 CW

= 21.5 CW

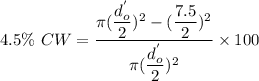

Now, after the first drawing, let the final diameter be

; Then:

; Then:

By solving:

To meet all of the criteria raised by the question, we must first draw a wire with a diameter of 8.46 mm and then 21.5 percent CW on it.