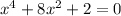

The given equation is,

Fundamental Theorem of Algebra says that a polynomial will have exactly as many roots as its degree (the degree is the highest exponent of the polynomial). A straightforward corollary of this (often stated as part of the FTOA) is that a polynomial of degree n with Complex (possibly Real) coefficients has exactly n Complex (possibly Real) zeros counting multiplicity.

Therefore, the equation will have 4 roots.

Descartes’s rule of signs says the number of positive roots is equal to changes in sign of f(x), therefore, the given equation does not have positive real roots.

Therefore, the equation will have 4 complex rooots.