Answer:

B) 0.0456

Step-by-step explanation:

It is given that :

Rationale :

UCL = 480

LCL = 480

∴ Mean ,

The standard deviation of sample (Sn) = 11.55

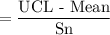

Z (for UCL)

= 2

Similarly,

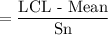

Z (for LCL)

= -2

Now using the z table for finding the confidence level between Z value of -2 and 2.

Confidence level = 0.4772 + 0.4772

= 0.9544

Risk (alpha) = 1 - confidence level

= 1 - 0.9544

= 0.0456