Answer:

a)

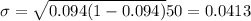

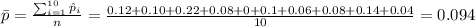

Now we can find the deviation with the following formula:

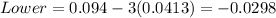

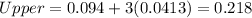

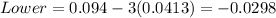

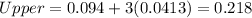

And we can find the control limits like this:

since a negative value not makes sense we can assume as lower limit 0.

since a negative value not makes sense we can assume as lower limit 0.

b) If we use Total quality management (TQM) tools help organizations to analyze and assess qualitative and quantitative data that is relevant to the producer. Is important to mention that that tools should be used in conjunction with other tools to understand the full scope of the issue with the bills.

We can use the Pareto principle that suggests that most effects come from relatively few causes. We can use for example Pareto charts in order to compare 'before and after' situations with the bills

Some sessions could result in a fish-bone chart can identify the possible causes of incorrect bills. Then a check sheet could be designed to collect data on the types of defects that occurred most frequently .

Step-by-step explanation:

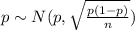

The population proportion have the following distribution

Part a

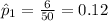

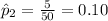

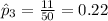

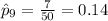

For this case we can calculate the proportion of defectives for each sample, and we take in count that each sample have a size of 50.

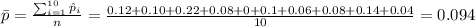

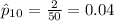

And in order to estimate

we can use the following formula:

we can use the following formula:

Now we can find the deviation with the following formula:

And we can find the control limits like this:

since a negative value not makes sense we can assume as lower limit 0.

since a negative value not makes sense we can assume as lower limit 0.

So then the control limits are Lower =0 and Upper= 0.218.

And if the proportion of samples is higher than 0.218 we have the process out of control.

Part b

If we use Total quality management (TQM) tools help organizations to analyze and assess qualitative and quantitative data that is relevant to the producer. Is important to mention that that tools should be used in conjunction with other tools to understand the full scope of the issue with the bills.

We can use the Pareto principle that suggests that most effects come from relatively few causes. We can use for example Pareto charts in order to compare 'before and after' situations with the bills

Some sessions could result in a fish-bone chart can identify the possible causes of incorrect bills. Then a check sheet could be designed to collect data on the types of defects that occurred most frequently .