Answer:

Step-by-step explanation:

Formulas:

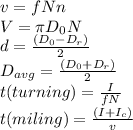

v=fNn

where

;

;

;

;

The cutting speed is the tangential speed of the workpiece

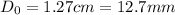

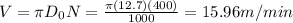

The maximum cutting speed is at the outer diameter and is obtained from the expression:

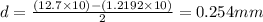

From the above given information, depth of cut is,

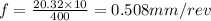

and the feed is,

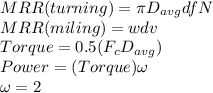

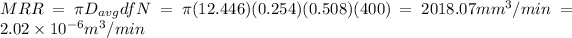

According to the given equation, the material removal rate (MRR) is,

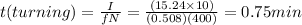

Actual time to cut, according to given formular,

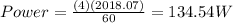

The power required can be calculated by referring to Table 21.2 and taking an average value for stainless steel as 4w-s/mm3. Therefore, the power dissipated is,

Since 1W = 60Nm/min, the power dissipated is 8072.4Mm/min.

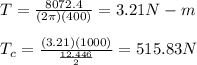

The cuting force is the tangential force exerted by the tool. Power is the product of torque T and the rotational speed in radius per unit time; hence,