Answer:

a)

b)

c)

Step-by-step explanation:

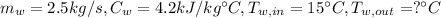

Water in:

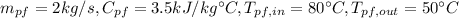

Process fluid in:

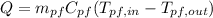

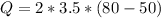

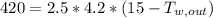

Step 1: Determine the rate of heat transfer in the heat exchanger

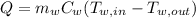

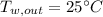

Step 2: Determine outlet temperature of water

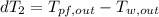

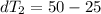

Part a) Parallel Flow

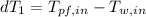

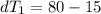

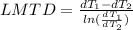

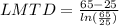

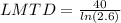

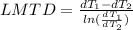

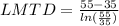

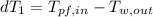

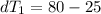

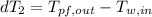

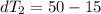

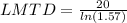

Step 3: Determine the Logarithmic Mean Temperature Difference (LMTD)

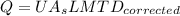

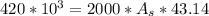

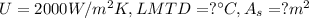

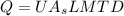

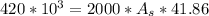

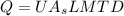

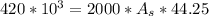

Step 4: Determine required surface area of heat exchanger

Part b) Counter Flow

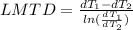

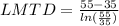

Step 3: Determine the Logarithmic Mean Temperature Difference (LMTD)

Step 4: Determine required surface area of heat exchanger

Part c) 1-2 shell and tube exchanger with the water on the shell side

Step 3: Determine the Logarithmic Mean Temperature Difference (LMTD) for counter flow

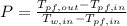

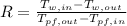

Step 4: Determine LMTD Correction Factor and Corrected LMTD

Correction factor F can be determined from attached graph using P and F values calculated above

Step 5: Determine required surface area of heat exchanger