Answer:

a. 864 units

b. 23.14 orders

c. $2,081

d. 10.8 days

e. 320

f. $221,081

Step-by-step explanation:

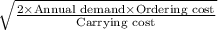

a. The computation of the economic order quantity is shown below:

=

where,

Annual demand = 80 units per day × 250 days = $40,000

And, the carrying cost = $10.95 × 22% = $2.409

The other items values would remain the same

Now put these values to the above formula

So, the value would be equal to

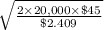

=

= 864 units

b. The number of orders would be equal to

= Annual demand ÷ economic order quantity

= $20,000 ÷ 864 units

= 23.14 orders

The average inventory would equal to

= Economic order quantity ÷ 2

= 864 units ÷ 2

= 432 units

c. The total cost of ordering cost and carrying cost equals to

Ordering cost = Number of orders × ordering cost per order

= 23.14 orders × $4 5

= $1,041.30

Carrying cost = average inventory × carrying cost per unit

= 432 units × $2.409

= $1040.688

So, the total would be

= $1,041.30+ $1,040.688

= $2,081

d. The number of days would be

= Economic order quantity ÷ daily demand

= 864 units ÷ 80 days

= 10.8 days

e. The reorder point would be

= Number of orders × demand level

= 4 days × 80

= 320

f. The total cost would be

= Annual demand × cost of each unit + total cost of ordering and carrying cost

= 20,000 × $10.95 + 2,081

= $221,081