Answer:

0.024 m = 24.07 mm

Step-by-step explanation:

1) Notation

= tensile stress = 200 Mpa

= tensile stress = 200 Mpa

= plane strain fracture toughness= 55 Mpa

= plane strain fracture toughness= 55 Mpa

= length of a surface crack (Variable of interest)

= length of a surface crack (Variable of interest)

2) Definition and Formulas

The Tensile strength is the ability of a material to withstand a pulling force. It is customarily measured in units (F/A), like the pressure. Is an important concept in engineering, especially in the fields of materials and structural engineering.

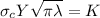

By definition we have the following formula for the tensile stress:

(1)

(1)

We are interested on the minimum length of a surface that will lead to a fracture, so we need to solve for

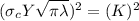

Multiplying both sides of equation (1) by

(2)

(2)

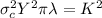

Sequaring both sides of equation (2):

(3)

(3)

Dividing both sides by

we got:

we got:

![\lambda=(1)/(\pi)[(K)/(Y\sigma_c)]^2](https://img.qammunity.org/2020/formulas/engineering/college/sa3uqssulzh23re1ojqhgliozd4zppzr0t.png) (4)

(4)

Replacing the values into equation (4) we got:

![\lambda=(1)/(\pi)[(55 Mpa√(m))/(1.0(200Mpa))]^2 =0.02407m](https://img.qammunity.org/2020/formulas/engineering/college/89d5g5ehqunf029bwhok9oyk9lggvc3ig6.png)

3) Final solution

So the minimum length of a surface crack that will lead to fracture, would be 24.07 mm or more.