Answer:

SiC=169.26 Mpa

Partially stabilized zirconia=507.77 Mpa

Step-by-step explanation:

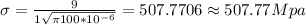

SiC

Stress intensity, K is given by

hence making

hence making

the subject where

the subject where

is applied stress, Y is shape factor, a is crack length

is applied stress, Y is shape factor, a is crack length

substituting the given figures and assuming shape factor, Y of 1

substituting the given figures and assuming shape factor, Y of 1

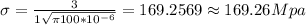

Stabilized zirconia

Stress intensity, K is given by

hence making

hence making

the subject where

the subject where

is applied stress, Y is shape factor, a is crack length

is applied stress, Y is shape factor, a is crack length

substituting the given figures and assuming shape factor, Y of 1

substituting the given figures and assuming shape factor, Y of 1