Answer:

If, p-value<α reject the null hypothesis, hence the production process is not really out of control.

Step-by-step explanation:

From the information, observe that a manufacturer considers his production process to be out of control when defects exceeds 3%. Consider a random sample of 85 items, the defect rate is 5.9%.

Here, The claim is that this is the only sample fluctuation and production is not really out of control.

Consider a null and alternative hypothesis:

Null hypothesis, H_o: The production process is not out of control when the defect does not exceed 3%.

that is H_o: p<=0.03

Alternative hypothesis, H_a: the production process to be out of control when defect exceeds 3%

That is H_a: p>0.03:

Level of significance α= 0.01

Test statistics under null hypothesis.

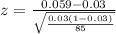

=

= 1.57

Calculative p-values as follows

P(z>1.57)= 1-P(z<=1.57)

= 1-0.9418

=0.0582

compare the p value with level significance

If, p-value<α reject the null hypothesis, hence the production process is not really out of control.