Answer:

Step-by-step explanation:

The word 'nun' for thickness, I will interpret in international units, that is, mm.

We will begin by defining the intensity factor for the steel through the relationship between the safety factor and the fracture resistance of the panel.

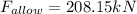

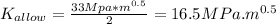

The equation is,

We know that

is 33Mpa*m^{0.5} and our Safety factor is 2,

is 33Mpa*m^{0.5} and our Safety factor is 2,

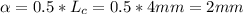

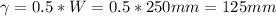

Now we will need to find the average width of both the crack and the panel, these values are found by multiplying the measured values given by 1/2

For the crack;

For the panel

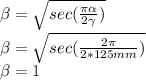

To find now the goemetry factor we need to use this equation

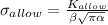

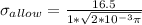

That allow us to determine the allowable nominal stress,

\sigma_{allow} = 208.15Mpa

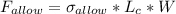

So to get the force we need only to apply the equation of Force, where

That is the maximum tensile load before a catastrophic failure.