Answer:

EOQ 30,984 (no discounts)

with discounts: 40,000

Step-by-step explanation:

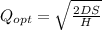

To know the best order quantity we use the Economic Order Quantity:

Where:

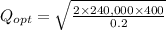

D = annual demand = 20,000 per month x 12 months = 240,000 anual demand

S= setup cost = ordering cost $400

H= Holding Cost = $1 x 20% = 0.20

EOQ = 30,983.86677

EOQ = 30,984

Now, considering there is a discount, we must check the EOQ against the next discount bracket.

below EOQ the order has less discount or equal discount, so the EOC should provide better cost.

At EOQ:

240,000 x 0.98 = 235,200

240,000/30,984 = 7.75 order per year x $400 = 3,100

30,984/2 = 15,492 average inventory x 0.2 holding cost = 3,098.4

Total Cost: 241.398,4

At 40,000 the cost is 0.96 per plywood:

240,000 x 0.96 = 230,400

240,000/40,000 = 12 order x $ 400 = $ 4,800

40,000/2 = 20,000 average inventory x 0.2 holding cost: $ 4,000

Total Cost: 239,200

after taking the discount into account the best deal is to take orders for 40,000 units

Increasing this will increase the holding cost, thus increasing the inventory cost.