Answer:

7.3% percentage of the bearings produced will not be acceptable.

Explanation:

Consider the provided information.

Average diameter of the bearings it produces is .500 inches. A bearing is acceptable if its diameter is within .004 inches of this target value.

Let X is the normal random variable which represents the diameter of bearing.

Thus, 0.500-0.004<X<0.500+0.004

0.496<X<0.504

The bearings have normally distributed diameters with mean value .499 inches and standard deviation .002 inches.

Use the Z score formula:

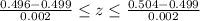

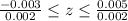

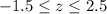

Therefore

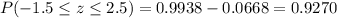

Now use the standard normal table and determine the probability of that a ball bearing will be acceptable.

We need to find the percentage of the bearings produced will not be acceptable.

So subtract it from 1 as shown.

1-0.9270=0.073

Hence, 7.3% percentage of the bearings produced will not be acceptable.