Answer:

Here Strain due to testing is greater than the strain due to yielding that is why computation of load is not possible.

Step-by-step explanation:

Given that

Yield strength ,Sy= 240 MPa

Tensile strength = 310 MPa

Elastic modulus ,E= 110 GPa

L=380 mm

ΔL = 1.9 mm

Lets find strain:

Case 1 :

Strain due to elongation (testing)

ε = ΔL/L

ε = 1.9/380

ε = 0.005

Case 2 :

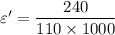

Strain due to yielding

ε '=0.0021

Here Strain due to testing is greater than the strain due to yielding that is why computation of load is not possible.

For computation of load strain due to testing should be less than the strain due to yielding.