Answer:

a) 0.0801

b) 80

Explanation:

The z-score for 13.825 is

The probability of producing a unit with weight less than 13.825 is

( Standard normal distribution table)

( Standard normal distribution table)

The z-score for 14.175 is

The probability of producing a unit with weight greater than 14.175 is

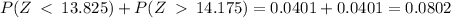

The probability of defect is

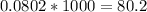

In a production run of 1000 parts, the expected number of defects is

To the nearest whole number 80 defects will be found