Answer:

Step-by-step explanation:

Given data:

length of Steel bolt

Length of aluminium cylinder

Pitch of bolt p = 1mm

Modulus of elasticity of steel E = 215 GPa

Modulus of elasticity of aluminium = 74 GP

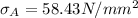

Area of bolt

Area of cylinder = 2300 mm^2

n =1

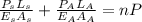

By equilibrium

By the compatibility

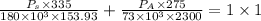

Displacement in steel is

Displacement in Aluminium is

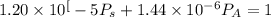

from compatibility equation we have

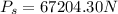

substitute

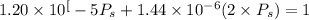

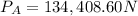

Stress in Aluminium