Answer:

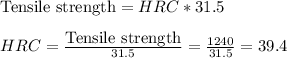

a) The minimum acceptable value is 387.5 HV using Vickers hardness test.

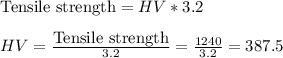

b) The minimum acceptable value is 39.4 HRC using Rockwell C hardness test.

Step-by-step explanation:

To get the tensile strength of a material from its hardness, we multiply it by an empirical constant that depends on things like yield strength, work-hardening, Poisson's ratio and geometrical factors. The incidence of cold-work varies this relationship.

According to DIN 50150 (a conversion table for hardness), the constant for Vickers hardness is ≈ 3.2 (an empirical approximate):

According to DIN 50150, the constant for Rockwell C hardness test is ≈31.5 around this values of tensile strength: